We manufacture and adapt any spindle on the market

生産性と作業工程および最終コストの改善を図っております。

Technology, innovation and experience all over the world.

In order to adapt to our customers’ most specific needs, we manufacture special spindles, adapted to their requirements. The large numbers of spindles manufactured by MYL over the last 45 years mean we can supply a wide range of models, adaptable to meet customers’ needs in an agile way. Thanks to the latest means of production, to the implementation of latest-generation technologies and the use of our own engineering resources we are in a position to produce any model of spindle. To do this, while meeting our customers’ demands, we use a software package developed especially for MYL, able to cope with processes in a unique, personalised way.

ID Grinding

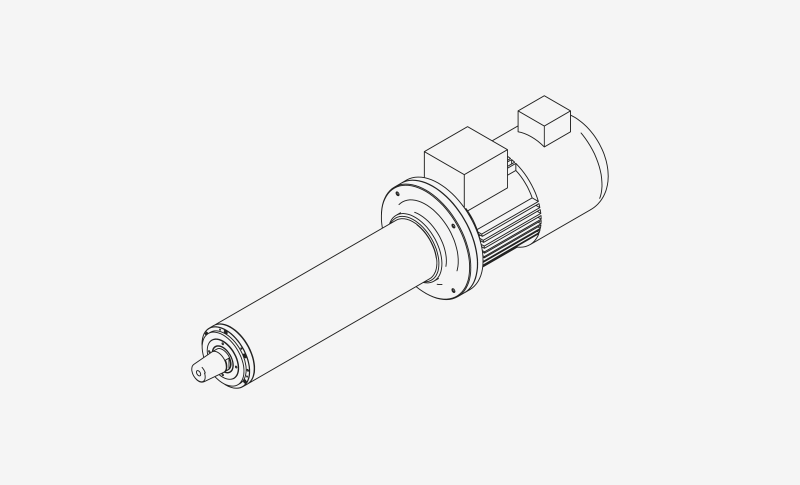

Mechanical transmission: Belt driven spindles for grinding internal diameters. Grinding from 2 mm diameter and lengths of up to 2000 mm. Air-oil or permanent grease lubrication.

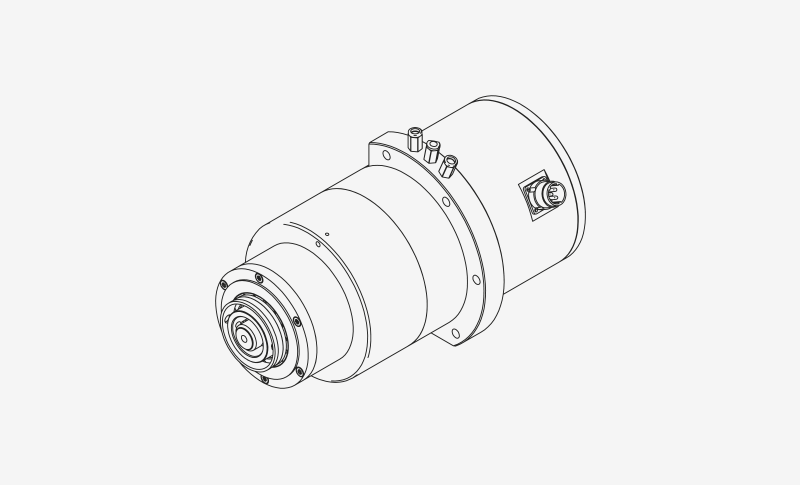

Motor transmission: High frequency motor driven spindles for grinding internal diameters. Synchronous and asynchronous integrated motors. Water or forced ventilation and cooling. Powers from 0.75 kW and working speeds of up to 120,000 rpm. Can be supplied with air-oil lubrication unit and frequency inverter.

OD Grinding

Mechanical transmission: Belt driven spindles for grinding external diameters. Incorporation of a radial force compensation system to prevent pulling of the belt. Options to add dynamic wheel balancing systems.

Motor transmission: High frequency motor driven spindles for grinding external diameters. Synchronous and asynchronous integrated motors. Water or forced ventilation cooling. Powers from 0.75 kW to 100 kW. Can be supplied with lubrication unit and frequency inverter. Automatic wheel change and dynamic balancing systems option.

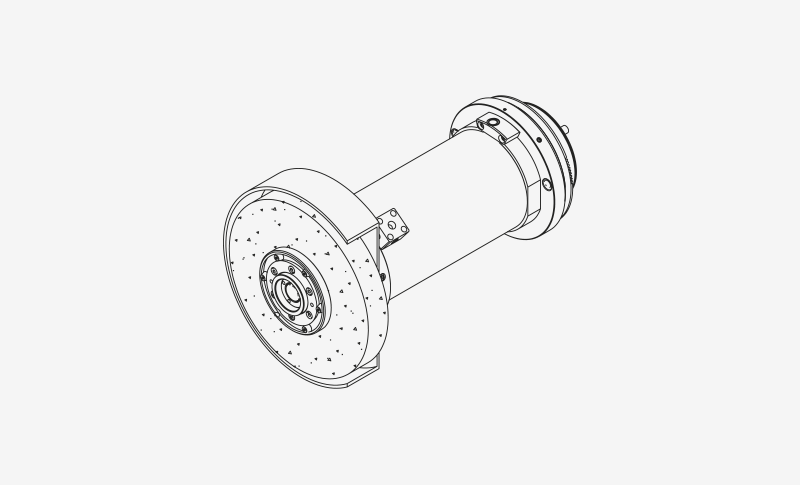

Hydrostatic external grinding

Mechanical transmission: Belt driven hydrostatic spindles for grinding internal diameters. Special pulleys with belt pull radial force compensation system. Bodies with clamps, wheel couplings and oil connectors in accordance with customer requirements. Can be supplied together with the hydraulic unit.

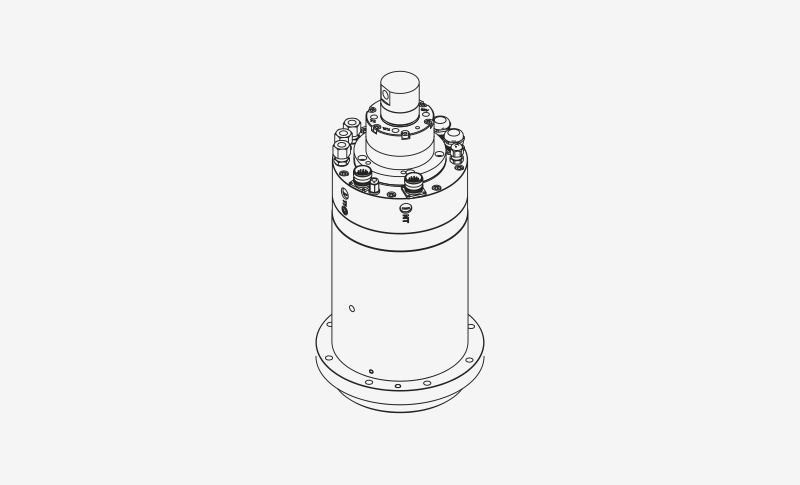

Motor transmission: High frequency motor driven hydrostatic spindles for grinding external diameters. Max 6000 rpm for grinding with CBN grinding wheels. Dynamic balancing systems. Bodies with clamps, wheel couplings and oil connectors in accordance with customer requirements.

Customized

Special spindles according to customer needs. Drive spindle for grinding. Grinding electro-spindle for gantry milling machine. External grinding units for rubber and polyurethane. Grinding spindles for vertical lathes with automatic spindle changing. External and internal grinding units for horizontal lathes. Wheel diamond dressers. Internal grinding units adapted to a CNC turning machine. Applications for frighten welding.

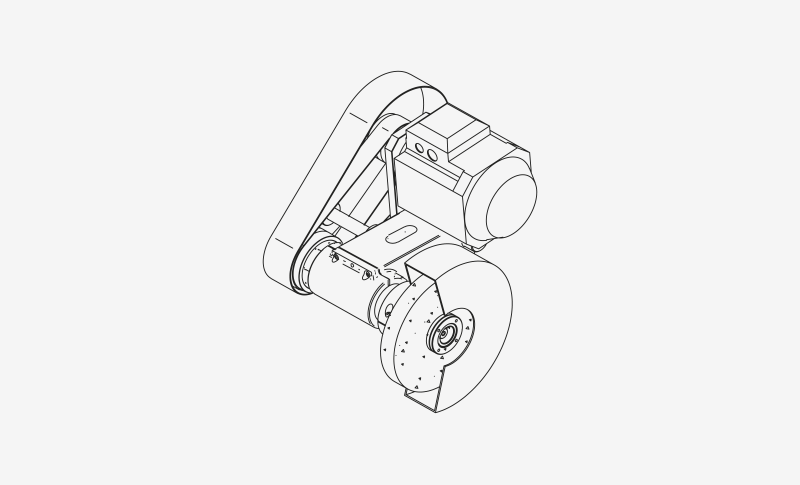

Tool post grinders

The MYL tool post grinders equipped with the renowned MYL grinding spindles are regularly used on lathes for external and internal grinding and front faces, as well as on planing machines and others.

Milling

Belt or direct motor driven milling spindles. ER, SK, HSK and special clamping systems. Grease and air-oil lubrication. Option to install accelerometers and temperature sensors for the bearings.